Keeping Screws and Fasteners Straight on a Metal Roof

Types of Fasteners:

Fasteners are often the most overlooked in terms of importance, yet possibly critical for any project. Screws or fasteners are available in various designs, shapes, sizes, and styles, each best suited for a purpose. When it comes to installing or repairing a metal roof, metal roofing fasteners are needed to anchor panels, shingles, or other parts to the main structure of the roof. Installation of fasteners prevents it from performing in the manner that it was intended to. In the long run, the metal roofing project can fail, which will lead to significant escalations in cost. Hence, it is imperative to use the correct metal roofing fasteners for any metal roofing project.

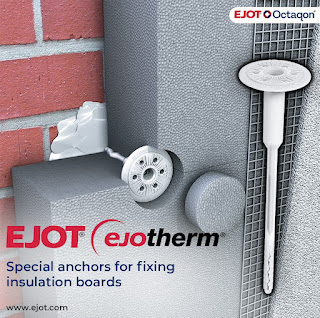

For any roofing project, there are multiple types of fasteners available from many manufacturers, including world leaders like EJOT. Flat roofs characterize most buildings and houses in India, unlike countries overseas. While this brings its own advantages, it also makes roofing, especially metal roofing projects, extremely challenging. However, solutions like Hex Head fasteners, Exposed Fasteners, Head Fasteners, Pancake Head Fasteners, Concealed Fasteners, and Cyclone washers for roofing screws manufactured using best-of-breed technology by manufacturers of all sizes. Using the correct screws or fasteners and installation tools helps to ensure an accurate, secure, and watertight attachment of the roof to the structure.

Proper installation of any metal roof is critical.

Most people who try to install roofs as a DIY project need to remember that any metal roof's longevity or long-term success depends on the correctness of its installation. The design of any roof will determine the number (thousands) of screws or fasteners needed. Not only will fasteners be required, but cyclone washers should ideally back each up for roofing screws. Unknown to many, these washers help seal the fastener in place and help seal the joint tightly. Using screws without washers to install a roof increases exposure to moisture, damage, and more significant problems.

Over and Under-Tightening of Screws:

A widespread error in any metal roofing project is the over or under-tightening of the metal roofing fasteners. If the screw is over-tightened, it creates a great deal of extra stress on the cyclone washer, causing it to break or bend, exposing the roof to leaks. Yet, on the other hand, under-tightening a screw despite using a washer still leads to leaks as the seal for the washer is not as tight as it needs to be. A good guide for determining the exact amount of tightening needed is using a screw gun set to the correct specifications. The gun's torque will ensure that all metal roofing fasteners have tightly and securely sealed, allowing for the washers to now make sure there are no leaks.

Fastening screws straight and ensuring that they are not crooked

It is vital to ensure that the screws are not fastened at an angle or are crooked during any roofing project. Any screw or fastener installed sideways or is tilted will create a gap between the fastener and the washer, which becomes a significant risk factor for leaks and exposure to the elements. Should this happen during the project, it is crucial to take the screw or fastener out and either replace it or reinstall it correctly and straight. The use of self-tapping screws coupled with cyclone washers for roofing screws and a screw gun will ensure that the screws or fasteners installed are straight and tightly secured, leaving no room for leaks.

Given the job's complexity, it is best to involve the services of a professional roofing company. These companies possess the tools, knowledge, and expertise to ensure that suitable materials and metal roofing fasteners are used and sealed shut using cyclone washers for roofing screws. For projects of this nature, it is essential to contract a skilled installation team known to pay attention to the smallest of details and who can guarantee successful results.

Comments

Post a Comment